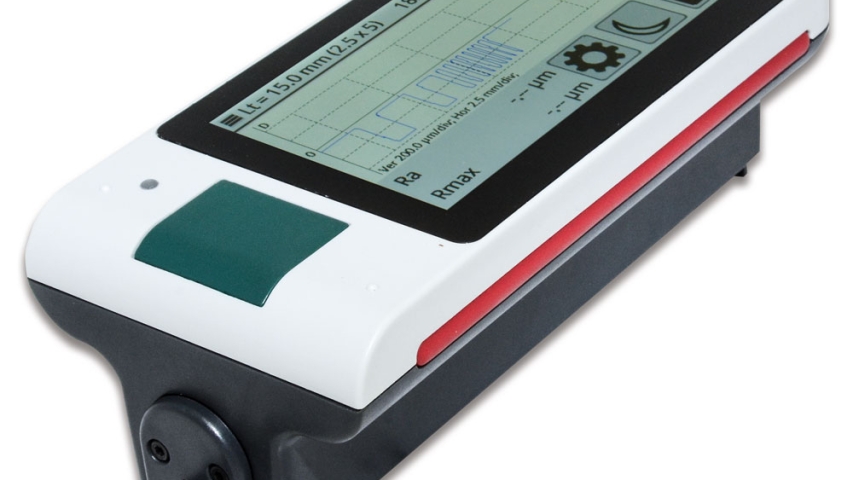

MarSurf PS10 Elcometer 7062 Surface Roughness Meter

The MarSurf PS10 Elcometer 7062 Surface Roughness Tester is a lightweight, portable measurement solution that can be used to carry out measurements required by international standards.

In anti-corrosion applications it is necessary to measure surface roughness.

With 31 surface parameters available, the Elcometer 7062 Surface Roughness Tester can display all parameters that comply with national and international standards.

These include peak-to-roughness profile measurement, combined with an assessment of the frequency of peaks in the sample.

The Elcometer 7062 is a lightweight, portable measurement solution that can be used to carry out measurements required by international standards.

It is also suitable for assessing surface roughness in a wide range of industries, especially those where parts are too large to be measured in the laboratory.

- Multi-language display: all relevant information is displayed, with a choice of 17 languages

- Flexible: can be used in almost any position; horizontal, vertical, upside down. Each instrument is supplied as standard with an accessory to adapt to different part shapes.

- Built-in roughness standard: no external calibration required, optimum ease of use

- Removable roughness standard: The roughness standard can be removed from the main unit and used with an extension cable (included) to allow measurement of hard-to-reach areas.

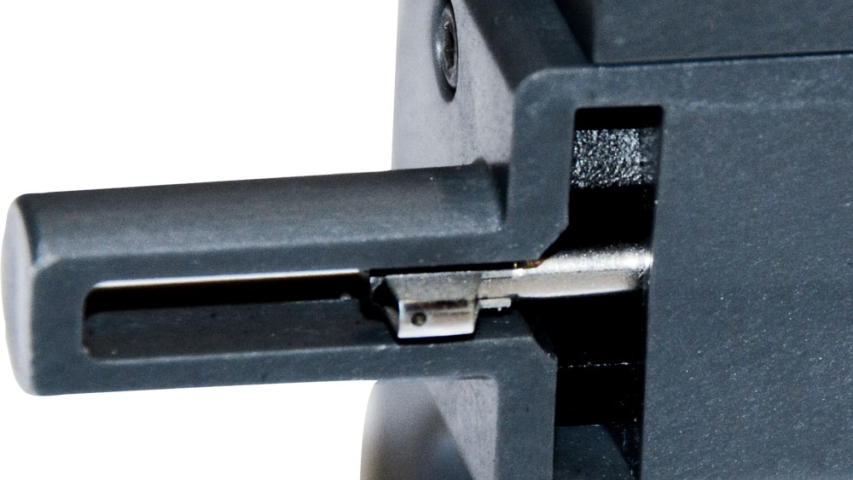

- Probe with removable protection: 2µm (80µin) diamond stylus with 0.7 mN measuring force. Wide choice of styli for various applications.

How to use a roughness tester

Roughness meters consist of a stylus that moves mechanically over a surface to record an 'image' of the surface roughness over a specified sample length. This measurement technique provides a large number of measurement parameters, including

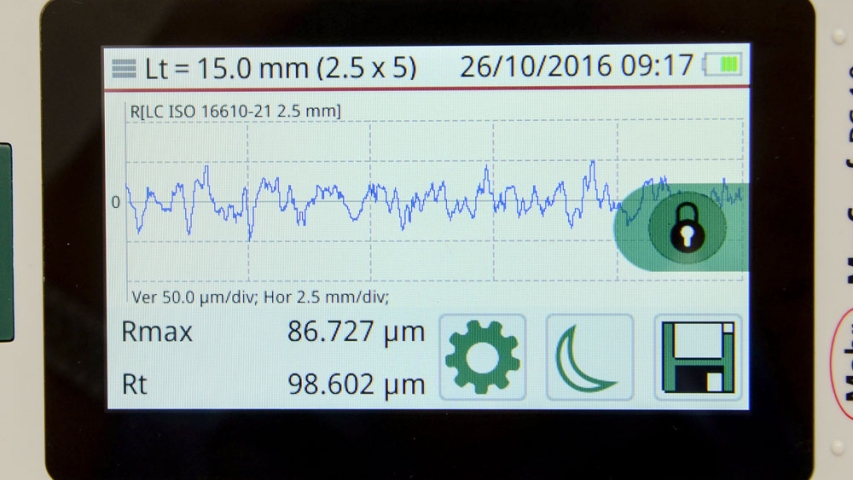

Rmax: largest protrusion-to-roughness deviation on an individual sample length out of the total evaluation length

Ra: average roughness over the length analysed

Rt: distance between the highest protrusion and the deepest trough over the evaluation length

Rz: average distance between the highest protrusion and the deepest trough over a number of lengths analysed

Spécifications

Units of Measurement

Metric, imperial

Principle of measurement

Probe method

Probe supplied (Other probe models available)

Inductive probe with shoe, probe tip 2µm (80µin), measuring force approx. 0.7 mN

Parameters

DIN/ISO

Ra, Rq, Rz, Rmax, Rp, Rpk, Rk, Rvk, Mr1, Mr2, A1, A2, Vo, Rt, R3z, RPc, Rmr, RSm, Rsk, CR, CF, CL, R, AR, Rx

JIS

Ra, Rq, Ry, RzJIS, tp, RSm, S

ASME

Rp, Rpm, RPc, Rsk, tp

MOTIF

R, AR, Rx, CR, CF, CL

Measurement range

350µm

Profile resolution

8nm

Filter

Phase-correct profile filter (Gaussian filter)

In accordance with DIN EN ISO 16610-21 (anciennement ISO 11562)

Special filter

In accordance with DIN EN ISO 13565-1

ls filter

In accordance with DIN EN ISO 3274 (can be deactivated)

Cutoff lc

0.25mm, 0.8mm, 2.5mm; automatique (0.010”, 0.030”, 0.100”)

Exploration length Lt

1.5mm, 4.8mm, 15mm; automatique (0.06”, 0.192”, 0.6”)

Exploration length (according to REASON)

1mm, 2mm, 4mm, 8mm, 12mm, 16mm (0.040”, 0.080”, 0.160”, 0.320”, 0.480”, 0.640”)

Short cutoff

Selectable

Evaluation length ln

1.25mm, 4.0mm, 12.50mm (0.050”, 0.15”, 0.50”)

Sampling lengths, number n

Réglable de 1 à 16

Calibration function

Dynamics

Memory capacity

3,900 profils, 500,000 résultats

Other functions

Lock settings (password protected), date/time

Verrouillage des paramètres (protection par mot de passe), date/heure

Rechargeable battery, power supply 100V to 264V

Interfaces

USB, MarConnect (RS232)

Dimensions

160mm × 77mm × 50mm (6.29” × 3.03” × 1.97”)

Weiight

500g (1.10lbs)

Long-range power supply Long-range power supply

100V à 264V

Packing list

Standards

ASTM D7127, ASME B46, DIN 4768, EN 10049, ISO 4287, ISO 4287/1, JIS B 0601, SSPC PA 17