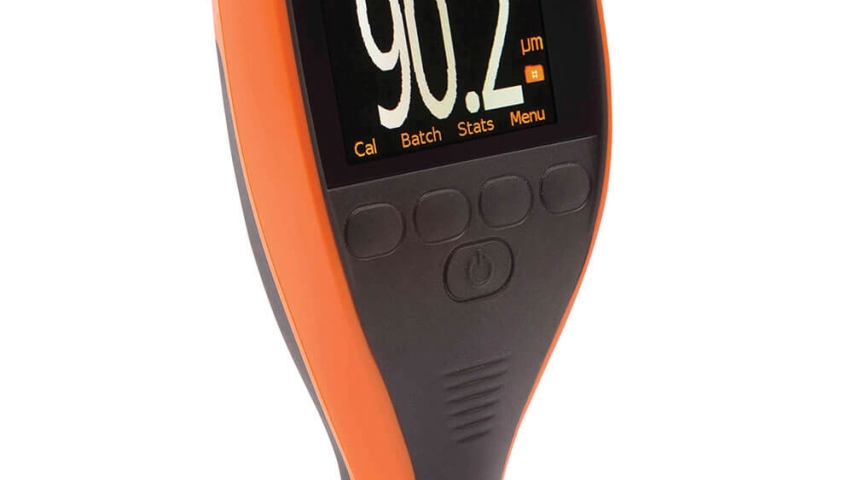

Elcometer 456 Integrated Probe Coating Thickness Gauge

The Elcometer 456 sets new standards, provides reliable and accurate coating thickness measurements and helps you to become more of a Performance Mode Batch Measurer.

The Elcometer 456 is now available in 3 different models. Each thickness gauge has new features - from the entry level model (Model B) to the most advanced model (Model T).

The integral probe gauges are ideal for one-handed operation thanks to the Bigfoot™ wide footprint probe which provides greater stability when taking measurements - enabling consistent, repeatable and accurate results.

Separate probe models, with their wide range of probes, allow even greater flexibility in taking measurements.

Using ElcoMaster® software and the ElcoMaster® Mobile App, measurements can be transferred via USB or Bluetooth® to a PC or iOS or Android™ mobile device for later analysis or report editing.

Halve your inspection time with the Elcometer 456 Coating Thickness Scan Probe

Fitted with a durable probe tip, the Scan Probe of the Elcometer 456 Coating Thickness Gauge offers a revolutionary design that allows the user to take dry film thickness measurements individually or by scanning large areas - without damage to the probe or coating.

When used in conjunction with the Scan or Auto Repeat mode of the Elcometer 456 Coating Thickness Gauge, the Scan probe can dramatically reduce dry film thickness measurement times without any loss of accuracy.

At a rate of 140 measurements per minute, the Elcometer 456 Coating Thickness Gauge Scan Probe allows a maximum number of inspections to be carried out in a minimum amount of time.

Key Features of the Elcometer 456 Coating Thickness Gauge:

Easy

- Large buttons, ideal when wearing gloves

- Simple menus in several languages

- High-contrast colour LCD display with automatic rotation

- Maximum and minimum measurement limit indicators

- Factory-calibrated for immediate use

Accurate

- Margin of measurement error of ±1

- Can be used in accordance with certain national and international standards

- Stable measurements regardless of temperature

- Best measurement accuracy for thin coatings

- Measures accurately on smooth, rough, thin or curved surfaces

Reliable

- Repeatable and reproducible measurements

- 2-year warranty

- Supplied with fully traceable test certificate

- Batch date and time function

Robust

- Waterproof, robust and shockproof

- Water and dust resistant to IP64 equivalent

- Scratch and solvent resistant display

- Durable gauge and probe construction

- Suitable for use in harsh environments

Efficient

- Fast reading rate of 70+ per minute, 140+ per minute with Scan Probe

- Storage of different calibrations

- Alphanumeric batch identification

- Calibration method selectable

- Compatible with ElcoMaster® and ElcoMaster® App Mobile

Powerful

- Wide range of interchangeable probes

- Data output via USB and Bluetooth® to iPhone* or Android™ devices

- Memory capacity of over 150,000 measurements in 2,500 batches

- Coating thickness measurements on metal substrates up to 31mm (1,220mils)

Importance of calibrating coating thickness gauges

Official quality systems, such as ISO 9001, require coating thickness gauges to be properly inspected, catalogued and calibrated. Increasingly, users are demanding traceability of measurements taken with coating thickness gauges to national standards.

To test the accuracy of a given thickness gauge, it is essential to have traceable thickness standards.

Elcometer offers a comprehensive range of certified shims with zero test plates capable of guaranteeing the accuracy of a thickness gauge.

Get the most out of your Elcometer 456 Coating Thickness Gauge and take full advantage of its ±1% accuracy by calibrating it to suit your application. This video shows various calibration options for both integral and separate probe models.

Avantages

- Easy

- Details

- Reliable

- Robust

- Effective

- Powerful

Spécifications

Technical specifications

Échelle 1

Measurement range: 0-1 500μm (0-60mils)

Accuracy*: ±1-3% or ±2.5μm (±0.1mil)

Resolution: 0,1μm: 0-100μm; 1μm: 100-1 500μm (0,01mil : 0-5mils; 0,1mil: 5-60mils)

Échelle 2

Measurement range: 0-5mm (0-200mils)

Accuracy*: ±1-3% or ±20μm (±1.0mil)

Resolution: 1μm: 0-1mm; 10μm: 1-5mm (0.1mil: 0-50mils; 1mil: 50-200mils)

For improved resolution and accuracy when measuring thin coatings, Scale 2 gauges can be converted to Scale 1 measurement mode.

Échelle 2

Measurement range: 0-13mm (0-500mils)

Accuracy*: ±1-3% or ±50μm (±2.0mils)

Resolution: 1μm: 0-2mm; 10μm: 2-13mm (0.1mil: 0-100mils; 1mil: 100-500mils)

Screen characteristics

Screen TFT colour QVGA 2,4” (6cm), 320 x 240 pixels

Type of batterey

2 x AA rechargeable batteries can be used

Autonomy

approx. 24 hours continuous use at one measurement per second

Gauge dimensions (h x l x w)

141 x 73 x 37mm (5.55 x 2.87 x 1.46")

Gauge weight

161g (5.68oz) batteries included

Recommended temperature

-10 to 50°C (14 to 122°F)

Packing list

Elcometer 456 Gauge, Calibration Sheets (integral probe only), Lanyard, Carrying Case (T), Protective Case (B, S, T), 1x Screen Protector (S, T), 2 AA Batteries, Operating Instructions, USB Cable (S,T), ElcoMaster® Software (S, T)

Standard

AS 2331.1.4, AS 3894.3-B, AS/NZS 1580.108.1, ASTM B 499,ASTM D 1186-B, ASTM D 1400,ASTM D 7091, ASTM E 376, ASTM G 12,BS 3900-C5-6B,

BS 3900-C5-6A, BS 5411-11, BS 5411-3,BS 5599,DIN 50981, DIN 50984, ECCA T1,EN 13523-1, IMO MSC.215(82), IMO MSC.244 (83), ISO 1461,

ISO 19840, ISO 2063, ISO 2178, ISO 2360, ISO 2808-6A, ISO 2808-6B,ISO 2808-7C, ISO 2808-7D, ISO 2808-12, NF T30-124, SS 184159,

SSPC PA 2, US Navy PPI 63101-000, US Navy NSI 009-32