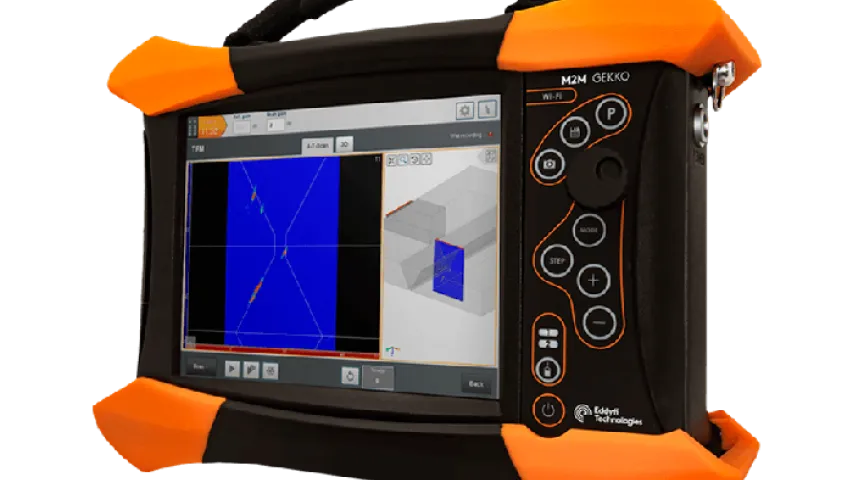

GEKKO Multi-element Ultrasonic Flaw Detector

Gekko is a field-proven flaw detector, offering PAUT, UT, TOFD and TFM through the simplified Capture™ user interface. Available in 32:128, 64:64 or 64:128 configuration, Gekko combines high resolution and speed while reducing inspector training time.

Gekko, the PAUT No. 1 unit with the Total Focus Method (TFM), has been improved based on feedback from inspectors. Gekko is the most versatile unit, adapted to field conditions.

A complete portable PAUT unit

Gekko includes all the basic and advanced functions of the UT in a compact, ruggedized package designed for field use. It comes natively with UT, conventional TOFD, and multi-element beamforming UT techniques for single-beam and multi-group inspection and its 3-axis encoding capabilities make the Gekko ready for any challenging inspection. This robust PAUT unit also offers real-time TFM/FMC (full raster capture) and adaptive TFM techniques.

Portable and robust

Bumpers and connectors are designed for ruggedness and accessory versatility. The bright resistive touchscreen allows outdoor use in harsh conditions. Powered by 2 hot-swappable batteries, Gekko now reaches 6 hours of autonomy and becomes the ultimate reference in its product range.

Compatible with most accessories

Delivered with an IPEX PA type connector and a LEMO16 encoder, Gekko is compatible with Eddyfi® accessories and with most probes and scanners on the market. For other configurations, Eddyfi can provide the adapter to ensure compatibility with your current accessory.

No compromise on performance

Innovative electronics offer up to 128 channels, excellent signal quality and TFM resolution for improved detection and confidence. It now achieves high scanning speed and productivity.

Fast connectivity solution

Connectivity solutions (dongle-enabled Wi-Fi™, USB 3.0 connector and Gigabit Ethernet output) help accelerate data transfer and control your inspection remotely in difficult conditions (TeamViewer license included). Additionally, the 256GB SSD makes the operator's work very comfortable with unlimited data file size, saving time in the field.

Avantages

- Increased accuracy with high-resolution imaging

- Robust field unit with high battery life

- Scalable software following feedback from inspectors

- Advanced Defect Analysis with Total Focus Method (TFM)

- Easy setup with built-in scan plans

Vidéo

Spécifications

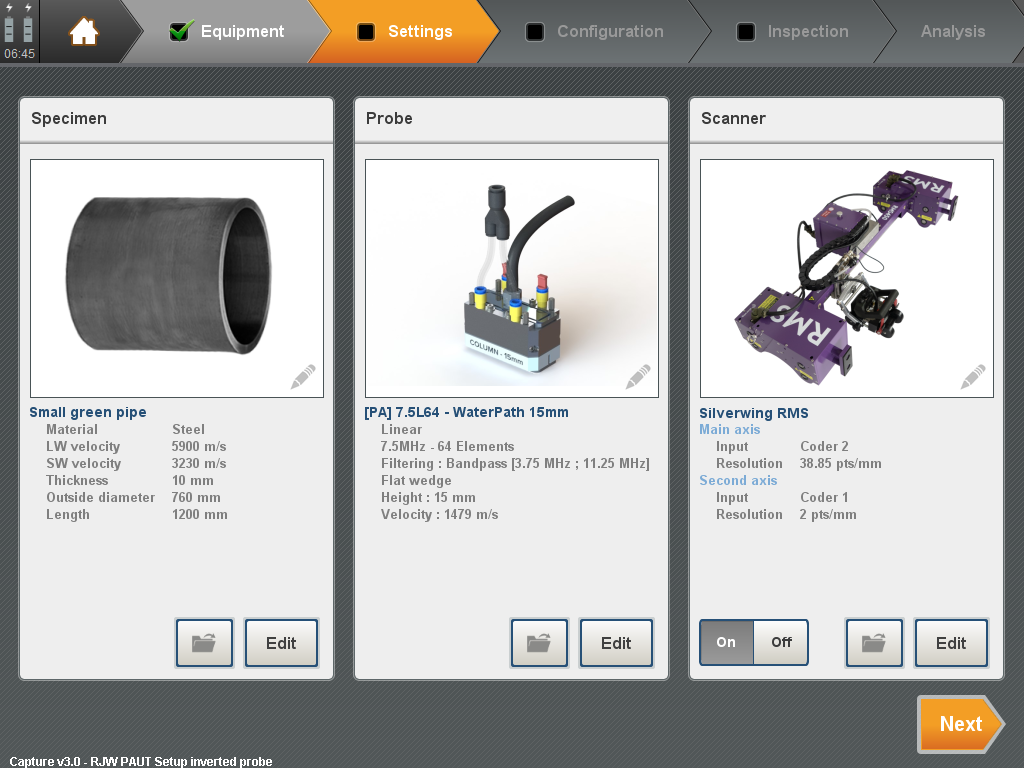

Simplified workflow

The next generation of Gekko, powered by Capture, was designed to ease the setup process and save time for inspectors operating in harsh environments. The built-in scan plan and newly added analysis features join popular 3-click wizards for assessing material velocity, balancing transducer amplitude, calibrating flat and curved corners, and than the automated TCG. Enhanced to provide an all-in-one inspection solution, from application design to inspection and reporting, Capture delivers the latest phased array technology in just a few clicks.

Unique characteristics

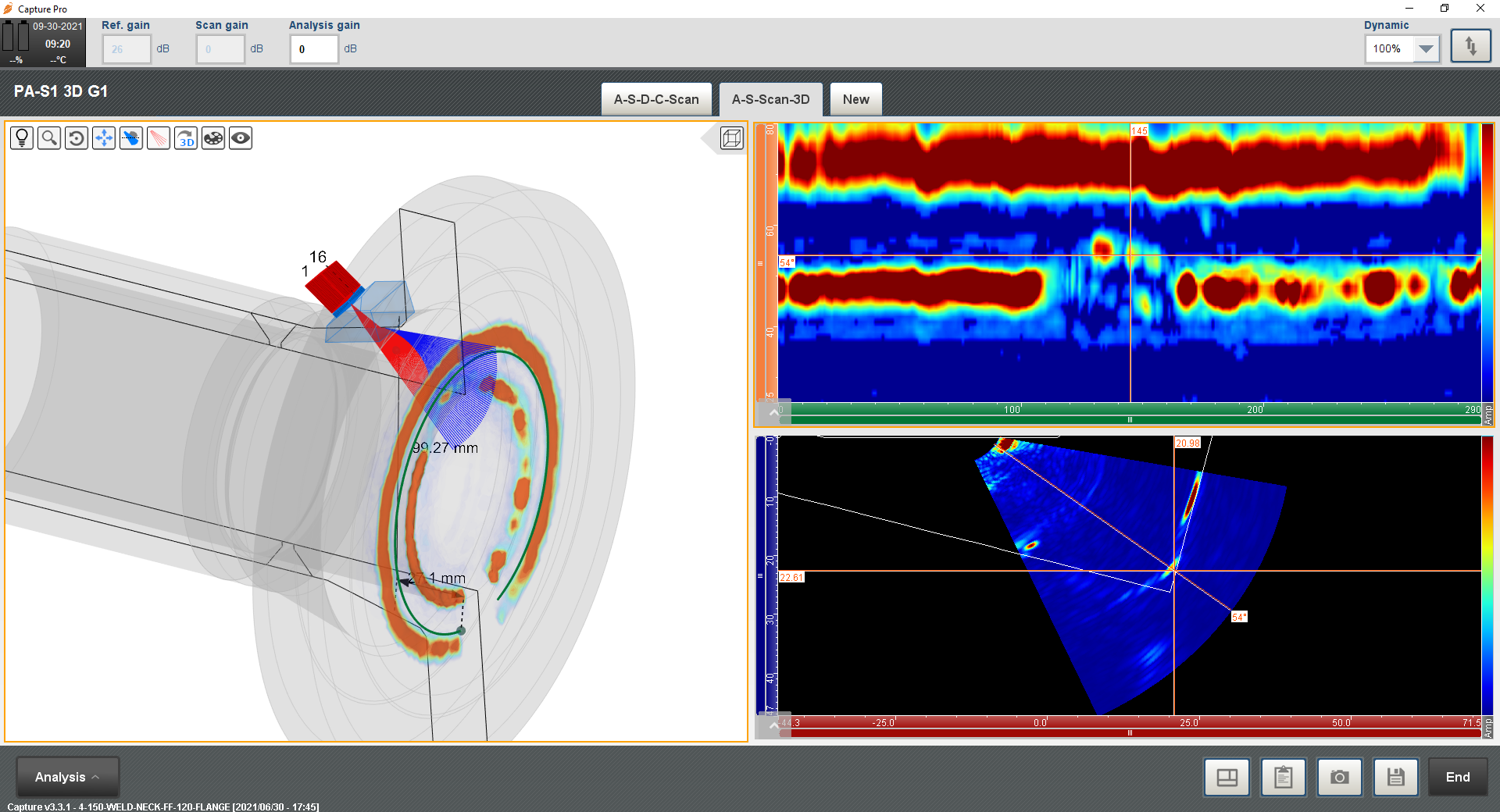

Complete toolkit for TFM including TCG calibration

High-resolution TFM imaging up to 128 elements

3-axis inspection nozzle with real-time display

3-axis brush for composite and corrosion mapping

Live view of fillet weld inspection

Adaptive real-time TFM (ATFM) for inspection of corrugated surfaces

INSTRUMENTS

Dimensions

410 × 284 × 126 mm

Weight

(with battery) 6.5 kg

Power source

15 V; 5.67 A

Batteries (hot swap capabilities)

Types: 2 × Li-ion, 94 Wh capacity

Typical lifespan: up to 6 hours

Display

26.4 cm resistive touchscreen

Screen resolution 1024 × 768 px

Memory space

256 GB SSD, expandable up to 1 TB

ENVIRONMENT

IP Rating

IP66

Operating temperature

10 to 45°C

Drop test

Selon MIL-STD-810G

Storage temperature range

With battery: 20 to 60°C

Without battery: 20 to 70°C

CONNECTIVITY

Several types of connectivity

Fast Gigabit Ethernet connection, Wi-Fi™ connection with USB dongle

1 × port Micro display

1 × IPEX PA Connector

3 × axis encoder input

1 × USB 3.0, 3 × USB 2.0

LEMO® 00 UT (4P/R) connectors

I/O 12 TTL (5 V/24 V), 6 × open collectors

MULTI-ELEMENTS

PAUT channel configurations

32:128 PR, 64:64 PR or 64:128 PR

Active opening up to 64 elements

Linear, matrix, double linear and double matrix matrices

Up to 8 beams | Up to 2,048 focal laws

Importing linear, sectoral, composite and CIVA laws

Phased array calculator powered by CIVA

Focus modes with constant and true depth sound projection and depth

Focal law calculator embedded on plates, pipes, fillet welds and nozzles

FMC/TFM

Real-time TFM up to 128 elements 256 kpi

Refresh rate up to 110 Hz at 65 kpi

Adaptive real-time TFM (ATFM)

All calibration wizards available

Image resolution greater than 4 Mpi in post-processing

Direct, indirect and converted modes

FMC registration

8 × manual resolution levels

1 × automatic resolution configuration

ACQUISITION

Material Acquisition Gates

PRF up to 40 kHz

Data flow on SSD up to 180 MB/s

Live 3D/overlay display

A-scan/peak data logging

Data compression up to 32x

Live missing data

Data file size: limited by SSD capacity