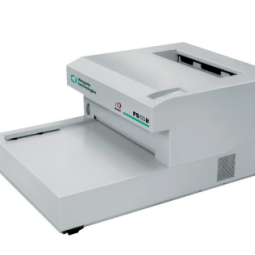

JME DXB:1 digital X-ray buggy

JME would like to introduce you to our new product, the DXB:1 digital X-ray buggy, designed to produce high-quality panoramic digital radiographs of circumferential welds in applications such as new pipelines. As a versatile and configurable system, it can also be used in various non-pipeline applications, such as inspecting tank walls or other ferrous metal structures.

This digital system is a replacement for traditional film radiography; hence, no more chemical processing, darkrooms, or defects associated with conventional radiography. The DXB features a high-definition digital panel for instant image quality verification and system parameters. Images are stored digitally, eliminating the need to store films and enabling permanent recording in the control tablet. These can be backed up via USB or using a network connection, allowing images to be sent to an on-site radiographer seconds after acquisition.

The JME DXB system also communicates and integrates with our entire range of CR2 pipeline crawlers. This enables bi-directional communication between the Pipeline Crawler and the DXB, providing configuration of key robot parameters from the DXB control tablet. This integration also enables inspection to commence with the push of a single button. The DXB operator is able to control, adjust, and view the status of the CR2 robot at any time during an inspection task.

With a quick magnetic deployment system, the DXB:1 can be positioned by a single person in less than a minute. The system is secured using permanent magnets, meaning that in the event of a power outage, the unit will remain securely attached to the pipe. This rapid and efficient deployment significantly increases productivity on-site. There is no need to deploy and move welding bands between each inspection, further enhancing on-site efficiency.

Avantages

- Deployed in seconds, no welding tape required

- Film replacement technology

- Enables "cloud-based" image inspection

- Fully integrated into crawler operation

- Integrated functionality with the CR2 remote control

- One-touch inspection

- Full safety locks

- Automatic image back-up

- Digital storage of images locally or on the Web

- Magnetic fixing

Vidéo

Spécifications

Global system specification

Buggy width

221 mm

Pipe diameter

Plat ou 13,5" (343 mm)

Average scanning speed

Minimum : 15 mm/s

Typique : 22 mm/s

(including imaging time and movement between images) - Depending on the pipeline programme

Image quality

Image quality class B according to: ISO19232-5, ISO 10893-7, ISO 17636-2

Image format

DICONDE-compliant data export via Ethernet or USB

Weight

Buggy, sensor and battery - < 44,1 lb (< 20 kg)

Dimensions (mm)

Global packaging kit - 687 (L) x 528 (L) x 552 (H)

Positioning

Manually positioned directly on the pipe. Cutting without strips

Operating temperature

-20°C à +50°C

Energy consumption

<50W

X-ray energy imaging

Up to 300 kV (depending on pipe wall thickness)

Image storage capacity

Over 500 images on a 36" tube

Imaging

Resolution

50-100 µm

Technology

CMOS

Image zone

Width : 110 mm

Length: up to 145 mm per image (depending on pipe diameter)

Image stitching

Uses image feature matching algorithm or optional buggy position encoder

Specification of the control panel

Display

10.1" capacitive 10-point multi-touch screen, LED backlighting for daylight visibility + Waterproof digitizer pen for improved ease of use

Certificate

MIL-STD-810G Certified IP65 Weatherproof design

Power supply option

Li-ion 11,1 V, 4200 mAh

Dimensions (mm)

269 (L) x 188 (L) x 20 (H)

Weight

2,4 lb (1,09 kg)

Système opérateur

Windows© 10 Professionnel

Buggy power supply options

Battery specifications (Dewalt Flex Volts)

54V 2000mAh

54V 3000mAh

54V 4000mAh

Control system

User interface

Touch screen with intuitive controls. Image viewing and evaluation functions for on-site verification of acquired images prior to formal interpretation.

Image acquisition

Automatic, user-controlled acquisition process.

Controlling crawlers

Full integration of robot control, to synchronise robot operations and image acquisition.