With the NOVOTEST application, you can:

- Adjust and calibrate the durometer.

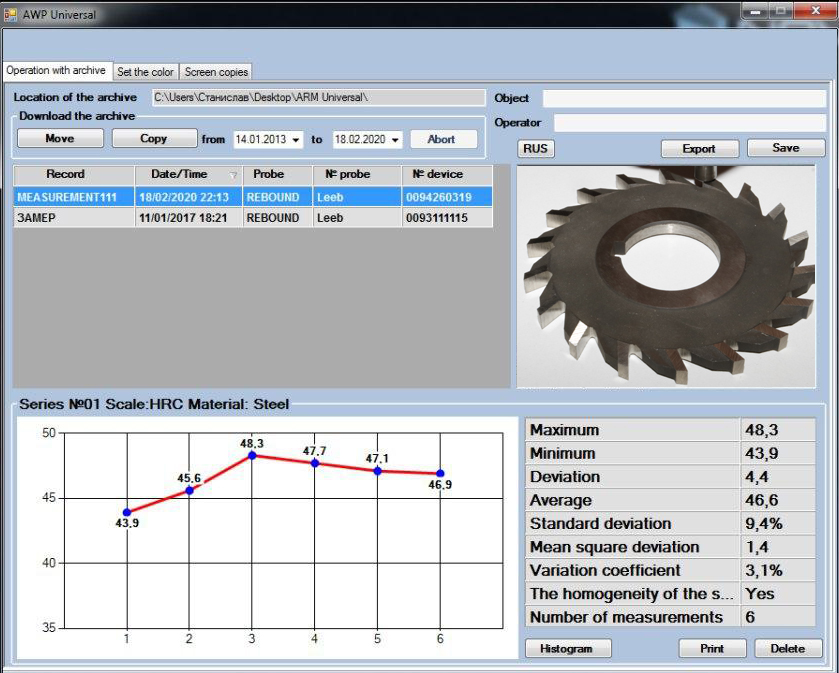

- Display measurement results in real-time as numerical values, with the option to construct graphs, histograms, or statistics.

- Take a photo of the tested object with hardness marks applied.

- Create a video of the tested product.

- Record audio notes of the tested object.

- Automatically save the geolocation of measurements on Google Maps.

- Display a Google map with markers of measurement locations and the ability to view these measurements.

- Show a measurement calendar (presenting the archive as measurements grouped by date).

- Generate a complete final report on the measurement.

- Send a completed report via email, messaging, or any other convenient method directly from the application.

- Have a flexible archive structure – similar to the usual file explorer, with the ability to create folders and files with any name.

- Synchronize with PCs and other smartphones.

- Cloud service for storing measurement archives.

- Automatically and manually synchronize measurement cloud archives between devices.

- Launch Google navigation mode, build a route, and accompany to the point where measurements were taken.

- Ability to store archives from other Bluetooth-enabled devices in a single application.

The main advantages of the NOVOTEST T-UD3 combined durometer:

CONNECTING BOTH METHODS WITHOUT TURNING OFF THE DEVICE

Users can measure the hardness of completely different metal products of different shapes, structures, materials, and surface preparation degrees with the same unit by simply replacing the probe.

MEASUREMENT OF SMALL PARTS

Using UCI, the operator can measure small products, with recommendations for parts weighing 100 grams and a thickness starting from 1 mm, and even finer when using the NOVOTEST UCI probe test bench.

MEASUREMENT OF COMPLEX-SHAPED PRODUCTS

Additionally, with the ultrasonic probe, the user can solve tasks of measuring hardness of grooves, small radius surfaces, inaccessible areas, and complex-shaped products.

SMALL FOOTPRINT OF THE UCI PROBE

Since the UCI probe has a penetration depth of only a few microns, it becomes possible to work with products with high print requirements (the maximum non-destructive method is required), as well as to measure the hardness of hardened layers, such as nitriding and carburizing.

MEASURING PARTS WITH POOR SURFACES

Using a dynamic probe (Leeb probe), the user can test the hardness of massive products with poorly prepared surfaces. The method also allows measuring products with coarse-grained structures without significant dispersion of measurements.

CALIBRATED FOR DIFFERENT MATERIALS AND SCALES

Thanks to the presence of built-in calibrations of the Leeb probe for various materials and scales, the device becomes a universal tool for measuring the hardness of most common metals.

INTEGRATED CAMERA

The device has an integrated camera, allowing the user to store a measurement archive of images of the tested objects with a hardness link to a specific location on the product.

The NOVOTEST T-UD3 combined durometer can be used with special software to work with a saved archive of measurements. Alternatively, each recorded entry can be printed via a wireless printer, which can also be supplemented with the device.