Leeb Hardness Tester NOVOTEST T-D3

The most popular method in the world for testing metal hardness using a portable hardness tester is the Leeb method (ASTM A956). The so-called dynamic method of hardness determination is widespread due to its ease of use. The user does not need to have any special skills and/or knowledge in the field of hardness measurement; to perform the measurement, it is necessary to load the impact body of the device's probe, place the probe on the tested surface, press the trigger of the probe, and the hardness value will be displayed on the device screen.

This method is recommended for large-sized products, weighing from 5 kg and with a thickness of 10 mm and above; however, by adhering to certain requirements for fixing the product, it is also possible to measure small parts.

Innovation! Optionally, the device can be equipped with a Bluetooth module!

Perform hardness measurements, calibrate the device, configure a convenient display of values, record the results of hardness measurements, synchronize the archive with your other devices and a PC, transfer measurement results to your colleagues—all this is available with your smartphone through the special NOVOTEST application for Android.

Hardness testers have never had such opportunities! With the help of a Bluetooth connection, your smartphone connects to the hardness tester, and you have an entirely new device—a next-generation hardness tester! The intuitive interface, numerous options for documenting results, internet access, touch screen, camera, microphone, and GPS receiver of a smartphone transform your durometer into something completely unique and previously inaccessible.

With the NOVOTEST application, you can:

- adjust and calibrate the hardness tester;

- display measurement results in real-time in digital form with the construction of a graph, histogram, or statistics;

- take a photo of the object to be tested with the application of hardness marks;

- create a video of the controlled product;

- record audio notes of the tested object;

- automatically save the geolocation of measurements on Google Maps;

- display a Google map with markers of measurement locations and the ability to view these measurements;

- display the measurement calendar (presentation of the archive in the form of measurements grouped by date);

- generate a complete final report on the measurement;

- send a completed report by email, messaging (or any other convenient way) directly from the application;

- flexible archive structure—completely similar to the usual explorer, with the ability to create folders and files with any name;

- synchronization with PC and other smartphones;

- cloud service for storing measurement archives;

- automatic and manual synchronization of measurement cloud archives between devices;

- launch Google navigation mode, build a route, and accompany to the point where the measurements were taken;

- the ability to store archives from other devices with Bluetooth in a single application.

The main advantages of the NOVOTEST T-D3 Leeb hardness tester:

Scales and Materials

The device comes with preliminary calibrations for various scales and materials, making the device universal.

Scales: HRC, HRB, HB, HV, HL, MPa.

Materials: steel, alloy steel, cast iron, stainless steel, aluminum, bronze, brass, copper.

It can also be calibrated for any scale and any material (USER scale).

Low Requirement for Surface Quality and Material Structure

The NOVOTEST T-D3 Leeb hardness tester can be used for products with poorly prepared surfaces (roughness 3.2 Ra and above), as well as for materials with coarse grain structure, such as cast iron and others.

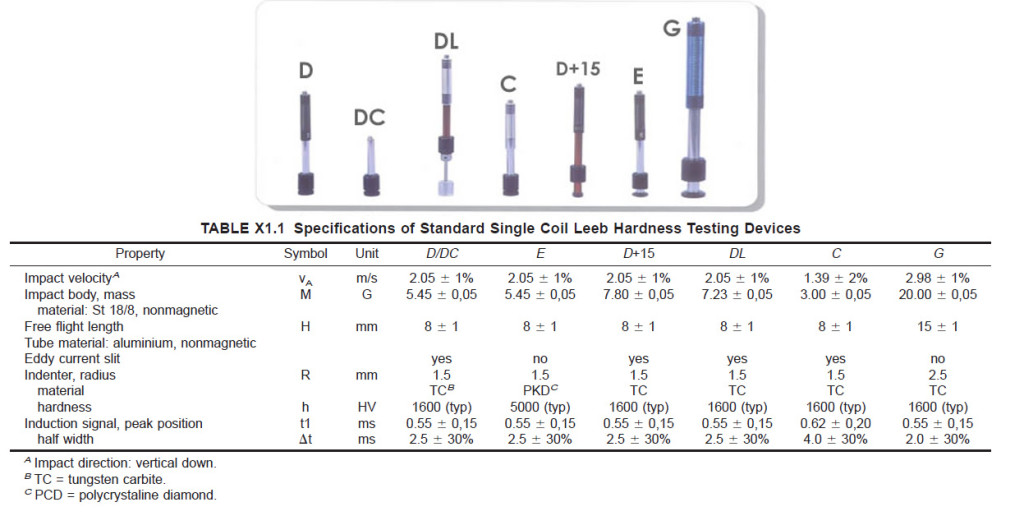

Various Types of Probes

The NOVOTEST T-D3 Leeb hardness tester can be used with different types of probes depending on the task and scope.

Avantages

- Large colour graphic display with bright backlighting

- Various measurement modes: statistical, graphical, histogram, intelligent, signal

- Calibration of any scale in any range

- Convenient and easy to measure

- Optimised number of buttons

- 88 combinations of materials and hardness scales (calibrations)

- Photofixation of test objects

- Extended temperature range (frost, down to - 40°C)

- Internal memory and communication with PC

- New intuitive menu with tips on the buttons

- Optional mini wireless printer

- Water-resistant casing

- Pare-chocs protégé en caoutchouc

Vidéo

Spécifications

Types of Leeb probes

D

DC

DL

C

D+15

E

G

Measurement range for steel

HRC:20~70

HB:90~650

HV:230~940

Résistance à la traction, MPa : 370~1740

Étalonnages utilisateur pour n'importe quelle gamme (par exemple : HV100-1600)

Measurement accuracy

HRC: 2HRC

HB : 10HB

HV : 15HV

Standards

ASTM A 956

ASTM E 140

ASTM A370

ISO 16859

DIN 50156

GB/T 17394

JB/T 9378

ISO 18265

Penetrator

Hard ball (Leeb)

Measuring direction

Any 360° direction

Data storage

Limited only by memory card up to 32 GB

Communication

Download data to PC and export as spreadsheet (USB cable and software included)

Hardness scale Leeb probe

HRC, HRB, HB, HV, HL, MPa

Additional custom scales for calibration

Material

Dynamic (Leeb) pre-calibrated for steel, alloy steel, cast iron, stainless steel, aluminium, bronze, brass, copper, etc.

Additional customised materials for calibration

Data display

Angle (Leeb)

Single test result

Max, Min, Average of tests

Number of tests

Deviation

Var. coeff.

Histogram

Signal and Smart Mode (Filtering out incorrect measurements)

Language

English, German, French, Polish, Russian

additional languages available on request

Indication

Colour LCD screen (320×240)

Operating environment

Temperature

-20°C~40°C

Humidity

30 % ~ 80 % HR