Hardness Tester UCI NOVOTEST T-U3

The most popular portable hardness tester in the world is the Leeb hardness tester, however, there are tasks that use this method that are very difficult, or even impossible to solve. This is due to the physics of the method, which assumes the massiveness of the object to be tested, to ensure the inertia of the product when the Leeb impact body strikes the surface with a given force. In order to solve a wider range of tasks on the rapid measurement of metal hardness, our company offers hardness testers that implement the ultrasonic contact impedance (UCI) method in accordance with ASTM A1038 standard. A vibrating rod (mechanical resonator) with a diamond tip acts as a penetrator in these devices, when it penetrates the material, the resonator's base frequency changes, based on which the hardness is calculated.

Innovation! Optionally, the device can be equipped with a Bluetooth module!

Perform hardness measurements, calibrate the device, set up a convenient display of values, save hardness measurement results, synchronize the archive with your other devices and a PC, transfer measurement results to your colleagues - all of this is available with your smartphone through the special NOVOTEST application for Android.

Hardness testers have never had such opportunities! With Bluetooth connectivity, your smartphone connects to the hardness tester and you have a brand new device - a next-generation hardness tester! The intuitive interface, numerous options for documenting results, internet access, touchscreen, camera, microphone, and GPS receiver of a smartphone transform your durometer into something completely unique and previously inaccessible.

With the NOVOTEST application, you can:

- Adjust and calibrate the durometer;

- Display measurement results in real-time in numerical form with the construction of a graph, histogram, or statistics;

- Take a photo of the object being tested with the addition of hardness marks;

- Create a video of the tested product;

- Record audio notes of the tested object;

- Automatically save the geolocation of measurements on Google Maps;

- Display a Google map with markers of the locations where measurements were taken and the ability to visualize these measurements;

- Display the measurement calendar (presenting the archive as measurements grouped by date);

- Generate a comprehensive final report on the measurement;

- Send a completed report via email, messaging (or any other convenient method) directly from the application;

- Flexible structure of the measurement archive - completely similar to the usual file explorer, with the ability to create folders and files with any name;

- Synchronize with PC and other smartphones;

- Cloud service for storing measurement archives;

- Automatic and manual synchronization of measurement cloud archives between devices;

- Launch Google navigation mode, build a route, and accompany to the point where measurements were taken;

- Ability to store archives from other Bluetooth-enabled devices in a single application.

The most modern and advanced ultrasonic device TM NOVOTEST is the NOVOTEST T-U3 UCI hardness tester, the main advantages of the device are:

MEASUREMENT OF THIN-WALLED PRODUCTS

The NOVOTEST T-U3 UCI hardness tester allows the user to measure products from 1 mm thickness without additional tools, and even less with the use of the NOVOTEST UCI probe test bench for thin sheets, making it unique among analogues.

MEASUREMENT OF SMALL PRODUCTS

With this device, the user can, without fixation and additional accessories, perform hardness tests on products weighing barely 100 g, or even less.

MEASUREMENT OF HARDNESS OF COMPLEX-SHAPED PRODUCTS

Unlike the standard Leeb probe, an ultrasonic hardness (UCI) probe only requires a surface of a few square millimeters to measure hardness. This allows users to measure hardness in hard-to-reach places, complex-shaped products, welds, heat-affected zones (HAZ), gear teeth, etc.

METHOD IS PRACTICALLY NON-DESTRUCTIVE

The footprint after hardness measurement by the UCI method is several microns and is practically not visible to the naked eye, compared to the Leeb method whose footprint is about 500 microns in diameter, depending on the hardness. It also allows for measuring the hardness of hardened material layers (nitriding, carburizing, etc.).

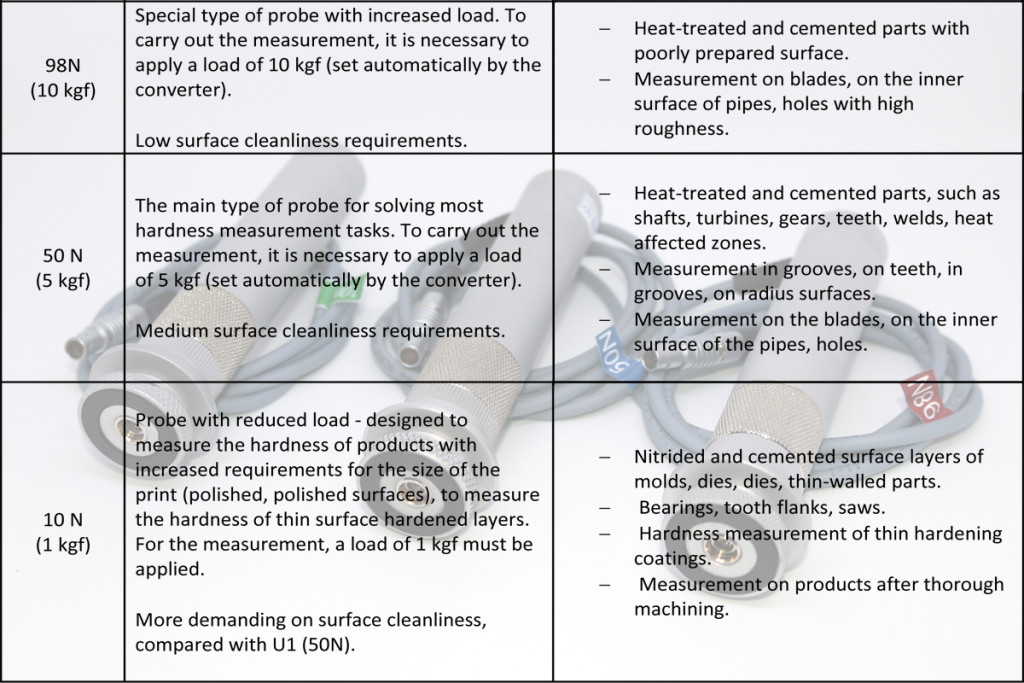

VARIOUS PROBE LOADS

As standard, the device comes with a probe whose penetrator penetration force is 50N (5 kgf), this probe is the most universal and solves 90% of the tasks that can be solved by this method. However, in specific cases, it is necessary to use probes with increased or reduced load on the resonator, the main characteristics and applications are presented in the table:

UNIVERSALITY OF PROBES

The probe of the NOVOTEST T-U3 UCI hardness tester has a special nozzle, which ensures the perpendicularity of the penetrator's penetration into the surface of the test object and minimizes the operator's error probability. Additionally, a special nozzle washer can be installed on the back for working with surfaces of different diameter radii. Similarly, it can be removed from the probe, in which case the fine nose of the probe can be installed in grooves or narrow points of the product, where hardness measurement is necessary.

ARCHIVING MEASUREMENT RESULTS WITH PHOTO FIXATION AND PRINTING THE PROTOCOL ON A WIRELESS PRINTER

The only portable durometer in the world with a built-in camera, which allows users to record the image of the tested object with fixed hardness value points on its surface. Additionally, the device can be equipped with a wireless printer, enabling users to quickly print a measurement protocol without leaving the test object.

UNIQUE RELIABILITY AND WARRANTY

NOVOTEST durometers are highly reliable. The ultrasonic hardness probe allows the user to perform over 200,000 measurements without the need for repairs or replacements, and the design of the electronic unit enables its use in fairly harsh operating conditions. Subject to operating rules, the durometer's lifespan exceeds 10 years.

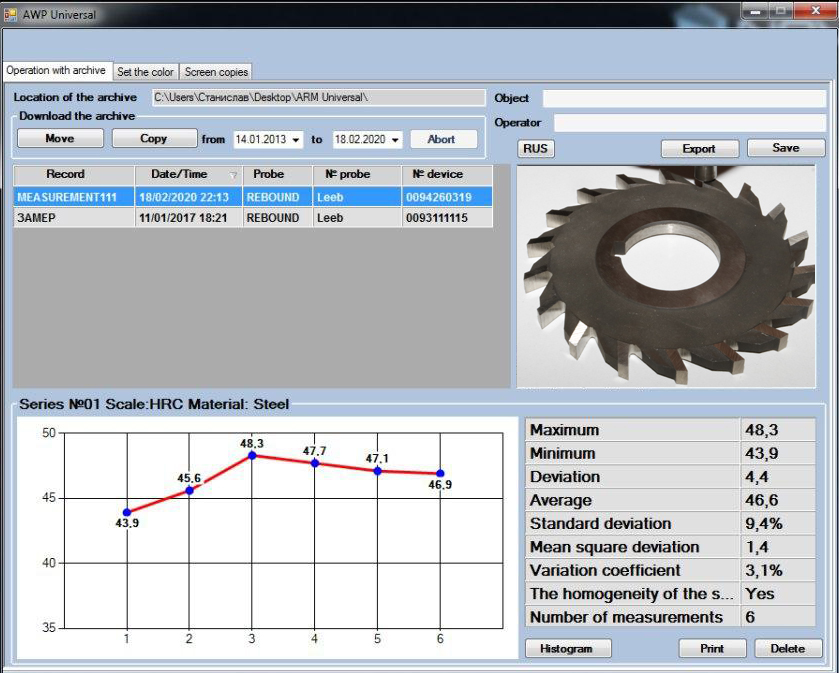

The NOVOTEST T-U3 UCI hardness tester also comes with special software for working with the device archive and subsequent data transfer for processing in convenient formats.

Avantages

- Hardness measurement of all bulk products thicker than 1 mm

- Measuring the hardness of the hardened surface layer

- Small impression after measurement (surfaces of shaft collar mirrors, blades, gear teeth, etc.)

- Wide range of hardness tests

- Different measurement modes

- Calibration of any scale in any range

- Convenient and easy to measure

- Optimised number of buttons

- Large colour graphic display with bright backlighting

- Calibrations stored in the sensor memory

- Extended temperature range (frost, down to - 40°C)

- Internal memory and communication with PC

- New intuitive menu with tips on the buttons

- Optional mini wireless printer

- Water-resistant casing

- Protected rubber bumper

- Different operating modes

Spécifications

Types of UCI probes

1kgf (10N)

2,2 lbf

5kgf (50N)

11lbf

10kgf (98N)

22lbf

Measurement range (with standard calibration)

CRH

20~70

HB

90~650

HV

230 ~ 940

User calibration for any range (e.g. HV100-1600)

Measurement accuracy

HRC

2HRC

HB

10HB

HV

15HV

Standards

ASTM A1038

ASTM E140

ISO 18265

DIN50159

GB/T 34205

Penetrator

Diamond indenter (UCI)

Sens de mesure

Toute direction 360°

Stockage de données

Limited only by the memory card

communication

Download data to PC and export as spreadsheet (USB cable and software included)

Hardness scale

HRC, HB, HV

Additional custom scales for calibration

Materials

Pre-calibrated for steel

Additional customised materials for calibration

Data display

Applied load/contact (UCI)

Single test result

Max, Min, Average of tests

Number of tests

Deviation Var. coeff.

Histogram Signal and Smart Mode (Filters out incorrect measurements)

Language

Anglais Allemand français polonais Russe

Additional languages available on request

Indication

Écran LCD couleur (320×240)

Operating environment

Temperature

-20°C~40°C

Humidity

30 % ~ 80 % HR