ECA and MFL REDDY surface corrosion detector

Equipped with the latest technologies, Reddy and its integrated data analysis software offer the most intuitive user experience, including real-time C-scans, a modern, robust, and large multitouch interface, as well as many other features enabling high probability of detection (PoD) surface inspections.

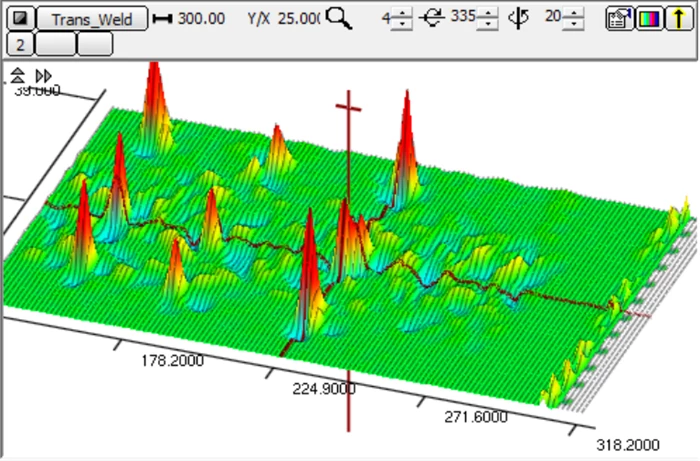

Detection and sizing of cracks in carbon steel welds

The Sharck™ is based on Tangential ECA (TECA™) technology specially developed for carbon steel cracking. This allows not only measuring the position and length of cracks but also sizing cracks up to 7 mm deep. Additionally, the Sharck allows simultaneous scanning of the weld cap, toe zone, and heat-affected zone to detect longitudinal and transverse cracks without surface preparation or paint removal.

Learn more about this application by watching our webinar with Marc Grenier.

Assessment of corrosion on ferromagnetic pipes, tank walls, etc.

MFL pipelines can adapt to a wide range of diameters (48 mm to flat surfaces). The magnetic flux leakage option allows you to fully leverage Reddy's versatility to quickly detect large surfaces for signs of corrosion. The sensor range provides extensive coverage and high PoD. Lifting and thick magnetic walls are now within reach.

Avantages

- Wide coverage and high-resolution ECA analysis for high PoD and faster inspection

- Intuitive C-scan imaging

- Configuration and in-depth analysis of desktop data with Magnifi

- Conçu pour une utilisation sur le terrain-robuste, scellé et conçu pour IP65AConfiguration et analyse approfondie des données de bureau avec Magnifi

Vidéo

Spécifications

Detection and sizing of cracks in stainless steel welds

Padded ECA probes accommodate geometric variations in almost any direction, making them ideal for examining weld seams, transitions and the heat-affected zone (HAZ). The probe's design allows the detection of surface cracks in welds with a minimum surface preparation of 0.5 to 1 mm. The probe's membrane is extremely resistant to friction.

Assessment of corrosion on aluminium and stainless steel tank floors

Semi-flexible ECA probes can accommodate the curvature of the tank bottom and other geometric features, providing sufficient penetration to allow scanning through thick steel/aluminium (greater than 6.35mm [0.25in]). The solution is thus able to detect and characterise corrosion-related defects, such as pitting and thinning, affecting only 10% of a plate's thickness.

Detection and assessment of stress corrosion cracking in base metal

I-Flex™ probes are the most versatile ECA probes in the industry. Thanks to their multiple integrated topologies and flexible bodies, they can address a wide range of applications. I-Flex probes are ideal for detecting stress-corrosion cracking (SCC) in ferrous and non-ferrous materials. Whether SCC affects the integrity of pipelines, pressure vessels or tanks (base metal or internally lined), coded analysis with I-Flex probes enables efficient cluster sizing.

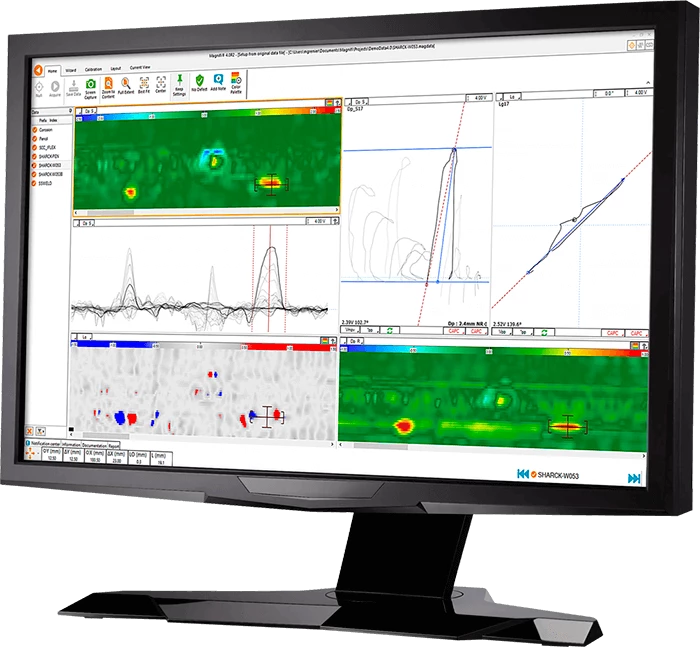

Magnifi CPN

This version of Magnifi® software allows you to perform advanced analysis of data acquired with Reddy directly on your computer. Magnifi CPN offers the same graphical user interface as Magnifi GO. So any analyst can be up and running in no time, with a wider range of larger monitor data configurations than Magnifi GO. This means that Reddy units can be acquiring data in the field while analysts are hard at work on their computers extracting value from the data. And with Magnifi CPN, you can easily plan and configure inspections for multiple instruments to get the most out of your equipment.

Dimensions

355 × 288 × 127 mm

Channels

32, 64 or 128 (each available with the MFL option)

Multiplexeur

SmartMUX™

Acquisition/sampling rate

Up to 50,000 samples/s

Weight

6,6 kg

Display

26.4 cm

Non-reflective (AR coating)

Anti-fingerprint (oleophobic coating)

3 mm chemically reinforced glass cover

Optically linked LCD and touchscreen

Passive black light enhancement

Encoders

2 × quadrature axes

Connectivity

Ethernet Gigabit, Wi-Fi™, Bluetooth®, HDMI, 3 × USB 2.0