MFL Multi-element scanner for FloormapX bin bottoms

Floormap ® X is the latest multi-technology solution for storage tank bottom inspection. It offers an unrivalled probability of detection - even in the critical zone - and can handle thick plates and coatings with flying colours. Thanks to patented STARS technology, it can determine where corrosion is located. Fast, it can be used in full floor mapping or Freescan™ mode. FloormapX increases your efficiency when inspecting tank bottoms like no other system.

Avantages

- Maximum coverage, including the critical zone

- High resolution for increased probability of detection

- Multi-technology fault discrimination (high and low)

- Flexible scanning, a scanner with three scanning/checking modes

- Inspect thicker plates up to 20 mm (3/4 in) thick

- Unrivalled, comprehensive and instantaneous reporting

- Ratio thresholds of up to 10%, to increase inspection intervals

- EEMUA 159 and API 653 compliant

Vidéo

Spécifications

Multi-technology solution

MFL Array: 64 channels, 128 multi-oriented MFL sensors, configuration. It produces the highest resolution imaging and market-leading probability of detection (PoD). On its own, MFL cannot differentiate whether corrosion is on the upper or lower side of the tank bottom.

STARS: The patented technology that enables FloormapX to differentiate between top and bottom corrosion and report them separately. STARS also generates detailed image profiles of the top surface, even in the presence of a coating, which provide vital information about the integrity of the tank.

Increased power: thicker plates and optimum detection probability

The advanced bridge design, which includes the most powerful rare-earth magnets, injects up to 30% more magnetic flux into the inspection surface than previous models. This, combined with an exceptional signal-to-noise ratio, enables FloormapX to detect smaller defects and inspect tank bottoms up to 20mm (3/4") thick with high sensitivity for the first time. The magnets can also be controlled and set to an 'off' condition for easier and safer handling, cleaning and transportation.

Maximum coverage, including critical area

Precision active steering facilitates inspection of the critical area up to 12mm from the shell wall, ensuring FloormapX maximises coverage in the most important areas. Its reduced profile and ability to tilt the handle also allows increased coverage under the pipe, enabling a more complete inspection.

Precise active steering

For fast, high-quality curved scans in the critical zone and elsewhere. This dramatically reduces dead zones by placing the sensors where they are needed most: less than 12 mm from the tank shell. Comes with the ability to return to straight-line driving at the touch of a button.

Interactive laser guide

Marking the ground as you map is now quick and easy, thanks to laser-assisted fault location. The laser line is simulated live in the C-scan, allowing you to correlate the physical location of defects on the reservoir floor with the C-scan indications.

SmartMAGNET

Variable automated magnetic flux intensity for optimised inspection performance based on plate thickness. Plus, literally turn off the powerful rare-earth permanent magnets for easier placement when inspecting, storing and shipping critical areas, and safer handling

Adjustable bridge height

Achieve maximum sensitivity where conditions allow and easily lift the bridge to scan even in the most difficult conditions, such as corrugated plates, plate repair and lap welds or where surface preparation is less than ideal.

Powerful integrated lighting

Dimmable, focused front LED with diffusing lens and rear LED. Based on on-board chip technology offering high and uniform intensity, in line with API recommendations for visual inspection, to perfectly highlight pitting and scanning obstacles on the product side.

Easy-break

Optimised design for intuitive, ergonomic magnet removal by operators.

Flexible inspection with 3 scanning modes

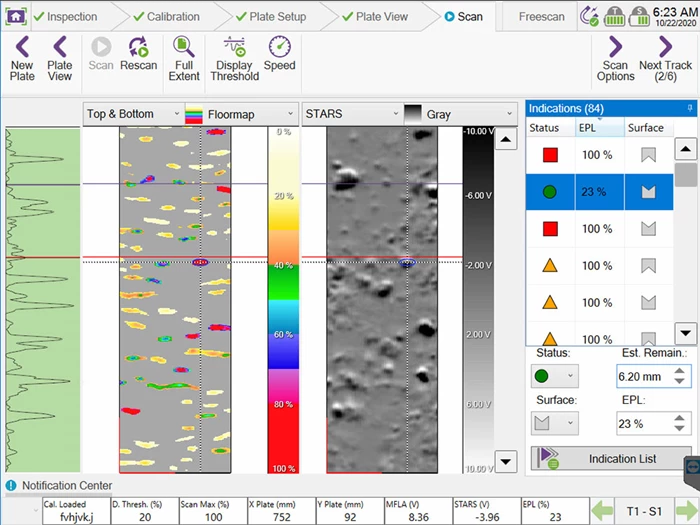

Mapping: a complete inspection with full auditable data sets. Query the inspection data in the tank or use the dedicated SIMS PRO TM desktop analysis and reporting software. During analysis, the operator can see live data for top and bottom defects.

Freescan TM: a simple and fast detection mode, exploiting all the underlying technology for the best possible result. A fast way to locate corrosion. Scan in any orientation, without having to measure the plates.

Pause on defect: a new feature integrated into the mapping and Freescan modes. Allows the scanner to pause during a fault search or check. Continue scanning without missing a step; the data will be transparent.

SIMS GO - Data acquisition

Intuitive software designed to increase workflow efficiency and produce accurate and complete tank inspection data. With a streamlined interface and operation, operators can select pre-planned workflows or create their own for both mapping and manual modes.

A first for Floormap is the real-time Live scan display during acquisition. An operator can view live MFL Array and STARS C-scan images. This is seamlessly combined with the ability to pause the scan and use the laser-assisted defect location function for fast and accurate defect location and identification: verification times have never been faster. Once proven, the operator can update the automated and editable indications list leading to a paperless reporting strategy.

sims go

Thanks to a minimalist approach to button clicks in the software, operators spend more quality time scanning and checking. An ergonomic button allows them to stop an analysis, move on to the next track, then start a new one.

Thanks to a minimalist approach to button clicks in the software, operators spend more quality time scanning and checking. An ergonomic button allows them to stop an analysis, move on to the next track, then start an analysis without removing their hands from the scanner handles or touching the tablet.

Once the inspection is complete, the removable tablet contains all the data needed to produce a customisable report in line with EEMUA 159 and API 653 recommendations.

SIMS PRO - Reports and more

SIMS PRO has been developed with customer feedback and engagement to provide a reporting solution that adheres to modern inspection requirements, including those outlined in EEMUA 159 and API 653.

Integrating seamlessly with FloormapX, SIMS PRO automatically displays inspection data in an intuitive and immersive way to provide a clear picture of the tank bottom condition, which is essential for designing optimal maintenance and repair strategies.

The FloormapX system combines seamlessly with the SIMS PRO software suite to deliver high quality, detailed inspection reports in the shortest possible time.

Principle of operation

Magnetic flux leakage (MFL) and magnetic field reluctance (STARS)

Discrimination

Yes, using STARS technology

Detection capacity

as little as 10%, ø 1 mm

Detection through coatings

Oui, si non-magnétique

Coating thickness

up to 10 mm

Speed

Variable from 500 mm/sec to 1 m/sec (19.7 in/sec to 3.28 ft/sec)

Scan width

300 mm

Inspection productivity

up to 263 m²/h

Plate thickness

4-20 mm

Battery

Up to 4 hours

Operating temperature

-10°C à 45°C

Real-time analysis

Fault size, × / Y position, plate view, up / down, MFL, MFLi, STARS