Under-insulation corrosion detector LYFT

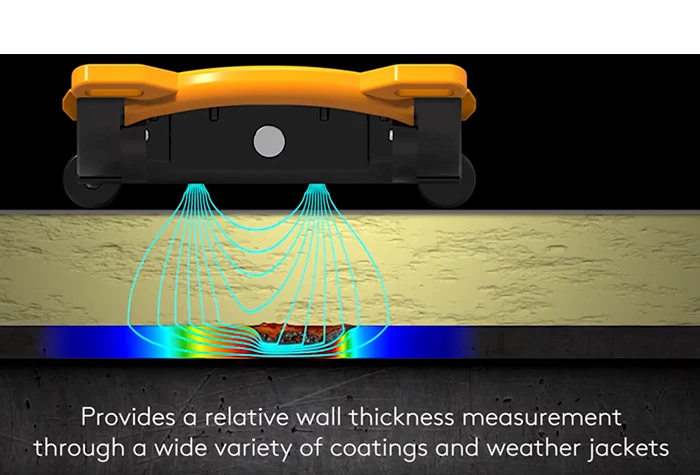

A flexible, fast, and reliable corrosion under insulation (CUI) integrity management solution. Lyft can scan through thick insulation, as well as aluminum, stainless steel, and galvanized steel jackets. It also benefits from a range of PECA, single-element PEC, and application-specific probes to support various applications. Who else but Eddyfi could reinvent an eddy current technique and redefine CUI programs.

Avantages

- Inspect through thick metal and insulation

- Save on insulation removal costs

- Real-time imaging for instant results

- One-touch automated reporting

- Rapid data acquisition

- Easy configuration with automatic optimisation of pulser and receiver parameters

Vidéo

Spécifications

CUI programmes redefined

Corrosion under insulation (CUI) is perhaps the biggest unsolved asset integrity problem in the industry. Current methods of measuring wall thickness on insulation (Liftoff) without removing it all have severe limitations. Lyft® is a high-performance solution that reinvents Pulsed Eddy Current (PEC).

Lyft can scan through thick insulation, as well as aluminium, stainless steel and galvanised steel jackets. It also benefits from a range of PECAs, single-element PECs and application-specific probes to support a variety of applications. Who else but EddyFi would reinvent eddy current technology, integrate a highly productive panel into the solution and completely redefine CUI programs?

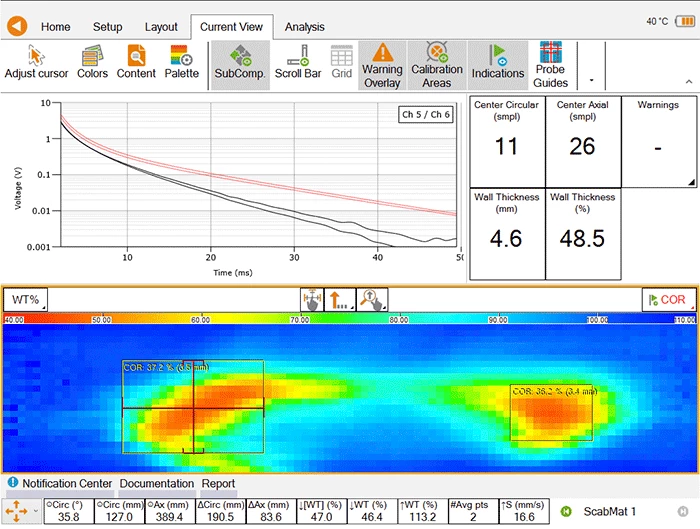

Automated software for reliable, reproducible results

cLa corrosion sous l'isolation (CUI) est peut-être le plus grand problème d'intégrité des actifs non résolu dans l'industrie. Les méthodes actuelles de mesure de l'épaisseur de la paroi sur l'isolation (Liftoff) sans la retirer présentent de sérieuses limitations. Lyft® est une solution haute performance qui réinvente les courants de Foucault pulsés (PEC).

Lyft peut scanner des isolations épaisses, ainsi que des enveloppes en aluminium, en acier inoxydable et en acier galvanisé. Il bénéficie également d'une gamme de PECA, de PEC à élément unique et de sondes spécifiques à l'application pour prendre en charge une variété d'applications. Qui d'autre qu'EddyFi réinventerait la technologie des courants de Foucault, intégrerait un panneau hautement productif dans la solution et redéfinirait complètement les programmes CUI ?

Unique to Lyft: wall thickness measurement tool for small defects

Undersizing is a well-known phenomenon in PECs, where defects smaller than the average probe area appear to be shallower than they actually are. Lyft's Compensated Wall Thickness (CWT) tool mitigates the phenomenon by quantifying the minimum wall thickness of a specific region in a C-scan. The CWT tool's specialised algorithms isolated a defect's contribution to the A-scan signal in order to calculate its minimum wall thickness more accurately.

Desktop analysis software

Lyft PRO enables advanced analysis of Lyft data and features the same graphical user interface as Lyft software, making it easier to gain insights and leverage larger data structures. This translates into data acquisition by Lyft instruments in the field, while analysts work to extract value from the acquired data. Lyft PRO makes it easy to schedule inspections of multiple Lyft instruments. The software also includes features to generate richer reports and tools to link calibration parameters between analysis areas. Available free to Lyft subscribers

SurfacePro3D is advanced visualization and reporting software designed to automatically create components and overlay assembled C-scan data. Use it to import Lyft reports, create 3D components and associate colour schemes automatically. Easily import, export, create and modify report templates. Compile and merge inspection data with associated images, inspection parameters and defect tables for fast, compelling reports.

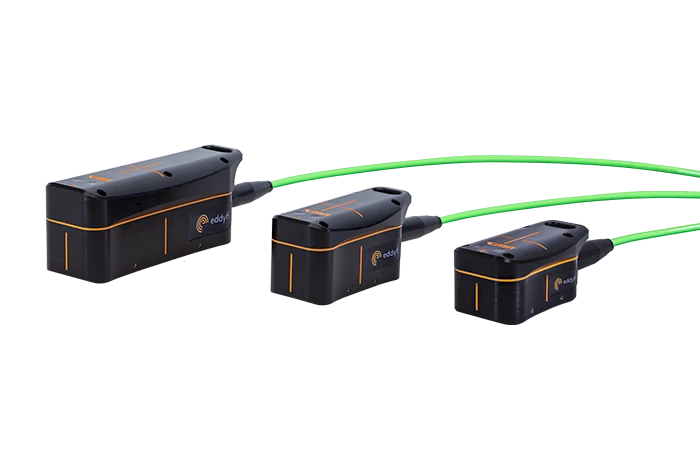

Optimised performance for wall thickness and lift-off The Lyft solution includes several plug-and-play probe sizes for the right balance between wall thickness and lift-off.

The high-productivity PECA probe is capable of covering a single 457mm pass in dynamic grid-coded or high-resolution mode. It supports metal thicknesses from 6 to 25 mm, insulation from 0 to 102 mm and stainless steel and aluminium protective jackets. IUC evaluation has never been faster, improving overall inspection productivity by up to 10 times.

The family of single-element PEC probes supports metal thicknesses up to 100 mm, insulation up to 300 mm and stainless steel/aluminium/galvanised steel sheaths. They complement the matrix probes for inspections with restricted access, small pipes and thick components..

Application-specific probes

The patent-pending high-resolution PECA probe is specifically designed for the inspection of corrosion-related crusts and blisters. Using a set of dual sensors capable of spatial triangulation, the probe can detect the smallest possible defects using PEC technology. It supports metal thicknesses from 3 to 19 mm, insulation from 0 to 50 mm and a single pass coverage of 75 mm in dynamic or network mode.

The tank bottom probe enables in-service inspection of storage tank annular rings. With its ultra-thin 4.8 mm thick titanium blade, the probe can slide up to 400 mm under the edges of the tank bottom, assessing the remaining wall thickness of this critical region exposed to corrosion. Integrated remote controls and status indicators are also ideal for one-person operation.

The patent-pending Galvanised Steel Coating Probe (PEC-GS) is specially designed to improve detection capabilities and sizing accuracy by reducing footprint dimensions to normal. The design neutralises sheath interference, improving signal penetration and preventing vibration from generating an unmatched signal-to-noise ratio.

Sondes Splash zone et Underwater

The splash zone probe can tackle offshore applications thanks to its robust design, waterproofing to 15 m in network mode and 25 m cable. The splash zone probe is flexible enough to withstand metal up to 76 mm thick and marine insulation or growth up to 203 mm thick.

Underwater probes can be used for deeper offshore applications. They are waterproof to 100 m and, thanks to the long extension lead, can be used with Lyft in grid mapping mode. Built-in status lights ensure better control and synchronisation with the topside team. The probes can be used on metals up to 100 mm thick, as well as insulation and marine materials up to 300 mm.

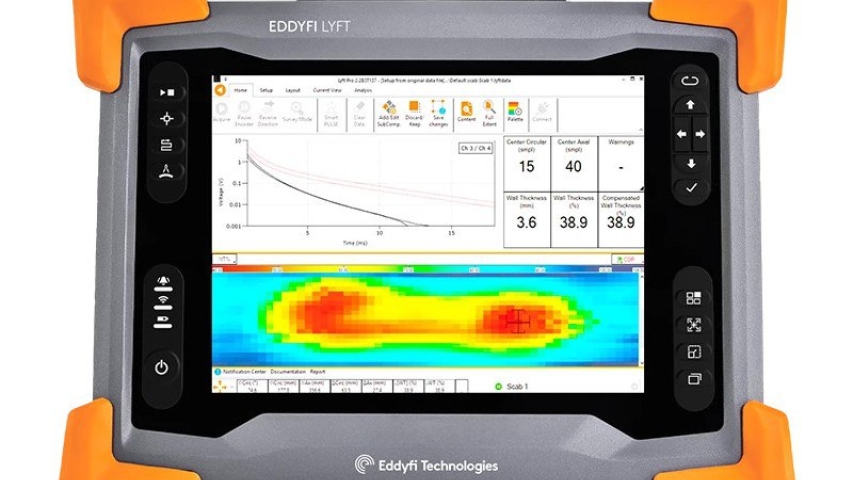

The best of ECP in a portable instrument

The Lyft instrument is sealed and rated to IP65. Its magnesium alloy housing is tough, water and dust resistant, and cools without external air exchange. The adjustable stand, top handle and four corner anchor points make it convenient for on-site inspections. The integrated, portable Windows® PC offers standard anywhere connectivity and advanced productivity tools to optimise field testing. The high-quality 26.4cm LED display is optically bonded, non-reflective, comes with 3mm toughened glass and is designed for gloved hands in all lighting conditions. The system also comes with two hot-swappable batteries for extended operation.

INSTRUMENTS

Dimensions (L x W x D)

355 × 288 × 127 mm

Weight (with batteries)

6,6 kg

Number of channels

7

Display

- 26.4 cm

- Multilayer

- Non-reflective (AR coating)

- Anti-fingerprint (oleophobic coating)

- 3 mm chemically strengthened glass

- Optically linked LCD and touchscreen

- Passive black light enhancement

Connectivity

Ethernet Gigabit, Wi-Fi™, Bluetooth®, 3 × USB 2.0

PERFORMANCE

Dynamic data acquisition

Up to 15 points/s

Dynamic scanning speed

Up to 75 mm/s

Scanning grid

Instantaneous, less than 1 second (typical)

SmartPULSE

- Automatic configuration of PEC transceiver parameters

- Full thickness sensitivity (OD and ID fault detection)

- Reliable measurements, even with variations in take-off, overlapping coats, straps and crusts

- Optimised repeatability

- One-point calibration (to nominal wall or known thickness value) and automatic normalisation

PROBES

- Clavier de commande a distance

- Connecteur Fischer Lyft 27 broches

- Câble robuste de 5 m

- Prise en charge de l'encodeur universel à prince

Nominal wall thickness

Up to 100 mm

Insulation (take-off)

- PECA-6CH-MED : 0–102 mm

- PEC-152G2 : 0 à 305 mm

- PEC-089-G2 : 0–203 mm

- PEC-025-G2 : 0–76 mm

Smallest detectable defect volume

15% of the volume of the impression (impression × wall thickness)

Min measurable remaining wall thickness

15 % de la valeur nominale

Weather protection jacket

- Stainless steel up to 1.5 mm

- Aluminium up to 1 mm

- Galvanised steel up to 1 mm

Pipe diameters

Up to 25 mm

Test temperatures

- Carbon steel structure temperature range: -150-500 °C

- Maximum temperature of outer jacket for direct contact operation: 70°C

- Maximum temperature of weather jacket with probe shoe: 120°C